* fixate the foundations of the structure to the ground (It is better to designthe foundation for the structure).

* Make sure the tank door is closed at all times.

* In areas where the air is too hot or cold, it is better to use foam andsuperfoam tanks to keep the water healthier and to protect it from ambienttemperature exchanges.

*Note that When installing the tank, it should be at least 15 cm away fromthe objects and side tanks on each side. This distance increases to 30 cmfor tanks larger than 3000 liters.

* If you stick the tank to the surrounding walls or to each other, it ispossible to break the tank due to the pressure that is applied to it and thelack of suitable space for shrinkage and expansion

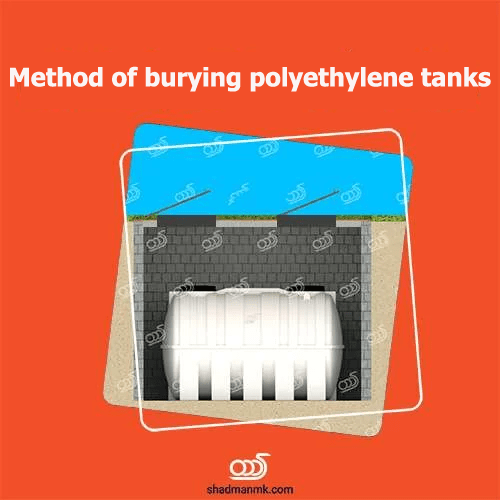

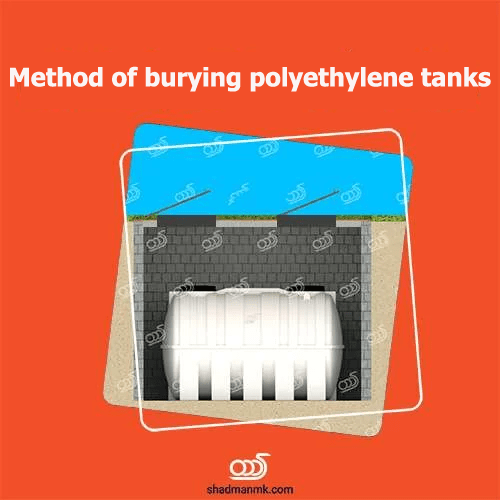

Considering that it is not possible to bury polyethylene tanks without building an

underground chamber, so you should pay attention to the following points:

First make a hole in the ground and then line the walls with suitable wall*

materials (consider the dimensions of the wall and the distance between

the tank and the walls, which is 15 cm for tanks under 3000 liters and 40 cm

above 3000 liters). It is better to consider space for convenience, visits and

etc.

Cover the inside of the hole with a wall (protective structure). Wallthickness should be designed according to environmental conditions, hole

depth, soil type and external pressure. be careful that polyethylene tanks

should not be subjected to external pressure.

Prepare the surface below the tank (described in previous posts).

Insert the tank into the pit.

If the hole is drilled in a place that is a passageway, design the roof

according to the environmental conditions and install a vent in front of the

tank door. In this case, the space above the tank to the ceiling is at least

one meter. This space is intended for visits and services. If you can not

make this distance, place the vent just above the tank lid at a short

distance.

In cases where the customer wants the water inlet and float to be close to the*

tank door. Can use this fin to install fittings or floats.

Very easy access to change or adjust the float in the middle door tanks. This

is a feature that this fin has created for middle door tanks

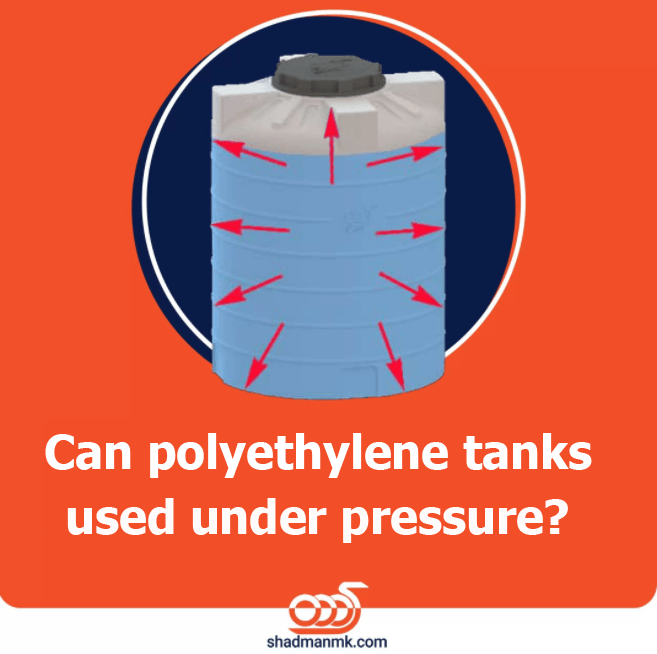

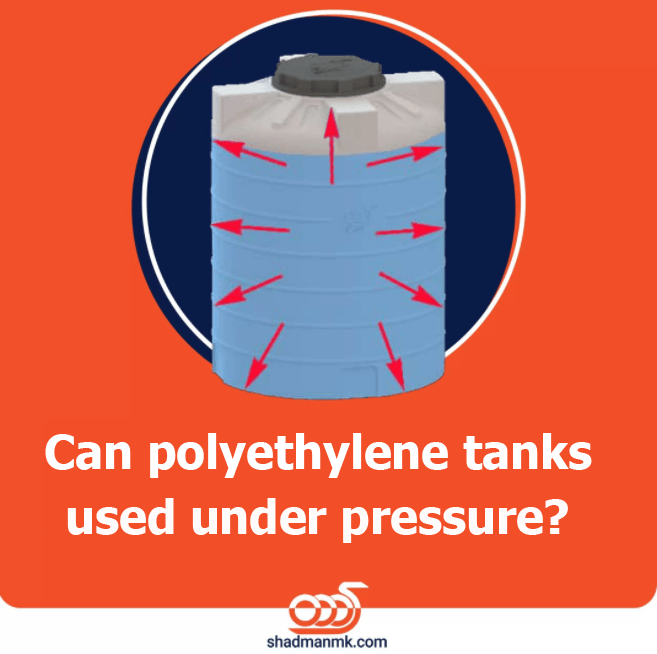

Can polyethylene tanks be used under pressure?

No. Polyethylene tanks must not be exposed to any internal or external pressure. These tanks are designed and produced only for storing liquids

Connections that can be installed on polyethylene tanks. The meaning of the

Connections are essentials Which are installed on polyethylene tanks to

prepare the installation of water inlet and outlet piping. Depending on the

type of liquid in the tank and the amount of consumption, its material and

dimensions change. Polyethylene fittings: These fittings are also available in all sizes. It has a number of o-rings, nuts and the main body, which should

be welded by experts after installation. they are the best and cheapest option

for consuming water and a wide range of acidic and alkaline substances and

chemicals that are corrosive to metals.

Stainless steel fittings: These fittings are used in special cases due to their

high price and have different grades for different materials and applications.

Brass fittings: Currently, the most common fittings can be installed on

polyethylene tanks, which are available in sizes from 1/2 inch to 4 inches. It

has a number of o-rings, nut, metal washers and the main body. Make sure

that the o-ring inside the tank and the metal washer and nut are placed

outside the tank to seal the connections.These connections are suitable for

water and non-corrosive materials.

Avoid placing any objects on the tanks.